- Home

- Pharma Production Equipment

- Pharmaceutical Granulator

- Traditional Chinese Medicine Pill Machine (for Large Pills)

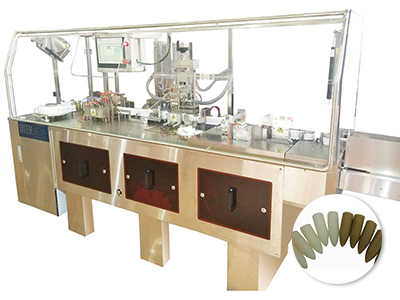

Traditional Chinese Medicine Pill Machine (for Large Pills)

Dier is capable of providing custom-manufactured pharmaceutical granulators with model options of three rollers, five rollers and six rollers, which are typically suitable for production of traditional Chinese medicine large pills of different viscosity and hardness. These traditional Chinese medicine pill machines feature high pass rate for pill production.

Videos

Choose Your Model

-

Model: DW-3 /DWS-3

- Output:≤ 300 kg/h (according to the pill specification)

- Pill specification:3, 6, 9, 10 g/pc

- Total power:5kw

- Air pressure :0.6 Mpa

- Air consumption :0.2 m³/min

- Dimension:1900×850×1800 mm

- Machine weight:800kg

Inquiry -

Model: DW-5

- Output:≤ 450 kg/h (according to the pill specification)

- Pill specification:3, 6, 9, 10 g/pc

- Total power:8.5kw

- Air pressure :0.65 Mpa

- Air consumption :0.2 m³/min

- Dimension:2700×2000×1550 mm

- Machine weight: 1500kg

Inquiry -

Model: DWS-6 /DWS-6-J

- Output:≤500 kg/h (according to the pill specification)

- Pill specification:3, 6, 9, 10 g/pc

- Total power:10 kw

- Air pressure :0.6 Mpa

- Air consumption :0.2 m³/min

- Dimension:2400×2300×1800 mm

- Machine weight: 1200kg

Inquiry

View Details

Features

- Pill rollers are driven by servo motor coupling with ball screw and linear guide, guaranteeing the smooth operation of rollers and stable running of the machine.

- Pill rollers and feeding section are coated with PTFE material, providing premium surface finish which prevents materials from being attached.

- Unqualified pills are automatically rejected and transferred through lift conveyor to storage tray, eliminating the need for manual operation.

- Improved roller structure ensures that pills are formed in round shape with even size.

- Drug strips are fed out in a uniform speed, enabling the spherical shaped pills to be produced with minimal weight difference in accordance with formulation.

- High automation and excellent sealing performance reduces the risks of cross-contamination.

- Heating unit is outfitted at the front end of drug strip out-feeding channel to rise the temperature and viscosity of the drug material, improving pill formation. Water cooling is also available, operator can select heating or cooling function according to the required drug viscosity.

- Appropriate height for material loading greatly reduces labor intensity, and the design of 90 degree rotation facilitates disassembly and cleaning.

Dier is specialized in the design, manufacture, sale and service of pharmaceutical manufacturing equipment and pharmaceutical packaging machines. Our pharmaceutical processing equipment including pill making machine, pharmaceutical dryer and suppository machine are all designed for the specific needs of pharmaceutical manufacturers and customers in pharmaceutical packaging sector. As an expert pharmaceutical processing and packaging equipment manufacturer, we are committed to satisfying the expectations of our customers by improving the efficiency, flexibility and reliability of our pharma machines. Not pharma equipment only, we also provide processing and packaging equipment applicable to food, cosmetic and other industries. Whether you need a single vertical packaging machine or hope to work with complete pharmaceutical production line, Dier can produce what you require in a timely manner.

DO YOU NEED MORE INFORMATION? CONTACT US!

- Add.: No. 16, Zhonghua Road, High-Tech Zone, Jiamusi City, Heilongjiang Province

- Tel.: +86-400-1178980

- Fax: +86-454-8782365